Dissemination

Conferences, oral presentations and invited lessons

- I.Urzica1, A. Simon1,2, C. Udrea” Manufacture of metal pattern by laser processing for microfluidic structures on polymers”, “CEEC-PCMS1 Conference – 1 st Central and Eastern European Conference on Physical Chemistry and Materials Science”, 26 th to 30th of July 2022, in Split, Croatia, poster.

- Cristian Udrea, Agota Simon, Iuliana Urzica, “Patterning of metallic molds surfaces by laser irradiation”, The International Conference on Lasers, Plasma, and Radiation – Science and Technology (ICLPR-ST), June 7-10, 2022, Bucharest, Romania, poster

- Iuliana Urzica, Catalin Logofatu, Agota Simon , Cristian Udrea , “Generation of superhydrophobic surfaces by exposure of materials to laser beams” TCM-TOEO 2022 Conference, 8th International Symposium on Transparent Conductive Materials &12th International Symposium on Transparent Oxide and Related Materials for Electronics and Optics, 16 – 21 October 2022, Heraklion, Crete, Greece , poster.

- Petronela Gheorghe, Petris Adrian , Ileana Rau, Pulsed laser emission in Rhodamine B - doped DNA biopolymer, International Scientific Conference on Applications of Chemistry in Nanosciences and Biomaterials Engineering, NanoBioMat 2022 – Summer Edition, oral presentation.

- I. Urzica, C; Logofatu, A; Simon and C. Udrea ,”Obtaining of superhydrophobic surfaces by nanosecond laser ablation”, SICT 2023 / PlasmaTech 2023 / Tribology 2023, 26-28 Avril, 2023 - Lisbon, Portugal, poster.

https://www.setcor.org/conferences/plasma-tech-2023/conference-program

- I. Urzica, A. Simion, P.C. Logofatu, C. Udrea, P. Gheorghe “Microfluidic properties of laser exposed metallic surface” 11th International Conference on Radiation, Natural Sciences, Medicine, Engineering, Technology and Ecology RAD11, June 19-23, 2023, Herceg Novi, Montenegro, poster.

https://drive.google.com/drive/folders/1_eV9BC2e4P8ihf0_sA1yPMCO3dfozWlp

- I. Urzica, A. Simion, C. Udrea, “Microfluidic properties of metallic surface using nanosecond laser ablation”, 6th International Conference on emerging technologies in materials engineering – EmergeMAT, 9-10 Novemeber 2023, Bucharest, Romania, poster. https://imnr.ro/wp/en/6th-international-conference-emergemat/

- P. Gheorghe E, A. Petris, A. M. Anton, I. Urzica, "Investigation of optical limiting properties in DNA-based materials", 6th International Conference on emerging technologies in materials engineering – EmergeMAT, 9-10 Novemeber 2023, Bucharest, Romania, poster.

https://imnr.ro/wp/en/6th-international-conference-emergemat/

- Cristian Udrea “Obtaining of superhydrophobic surfaces by nanosecond lasers", 8th International advanced School on Frontiers in Optics & Photonics , July 10-21, 2023, Yerevan Armenia, oral presentation.

- Mihaela Bojan, ”Frontiers in Microfluidics”, 8th International advanced School on

Frontiers in Optics & Photonics , July 10-21, 2023, Yerevan Armenia, oral presentation.

- Mihaela Bojan, Iuliana Urzica, Cristian Udrea, “Optical processing, spectroscopy and image encryption using the Fourier transform as a key analysis tool” ECONOS 2024, European Conference On Nonlinear Optical Spectroscopy,21-24 April 2024, Vienna, Austria, poster.

- Iuliana Urzica, “Frontiers in Microfluidics”,3rd Edition International Conference on Physics and Quantum Physics” scheduled during 25-26 Mar 2024 at Barcelona, Spain, invited presentation.

Methods and materials:

A method based on obtaining a pattern in order to replicate it generally involves three stages: creating the template/pattern (in our case a superhydrophobic surface with micro-nanostructures); a melding step, in which the polymeric materials are replicated on the surface of the template/pattern based on specific processing techniques; and a demoulding step, where the surface of the structured polymer is carefully detached from the surface of the pattern. One of the most common techniques for making patterns is laser ablation. In this work, a method based on a nanosecond laser is presented in order to obtain superhydrophobic surfaces on aluminium samples in order to replicate them on a polymer- PDMS. In this case, a nanosecond laser is used; laser that during the ablation process forms rough edges or burrs. Precisely these burrs help us to obtain a superhydrophobic surface, with a contact angle greater than 150°. However, the nanosecond pulsed laser is often used in industry to process materials. The ablation parameters of the nanosecond laser, such as the number of pulses, pulse width, wavelength, fluence, and laser Gaussian intensity distribution at the laser focus, significantly influence the resulting surface roughness

Laser parameters for surfaces texturing

|

Laser Parameters |

Values |

|

Wavelength |

355nm |

|

Beam energy |

0.6-130mJ |

|

Repetition rate |

10Hz |

|

Pulse duration |

6ns |

|

Scanning speed |

0,075 mm/s |

|

Distance per line |

3mm |

|

Number of pulses per line |

400 |

|

Distance between lines |

150µm |

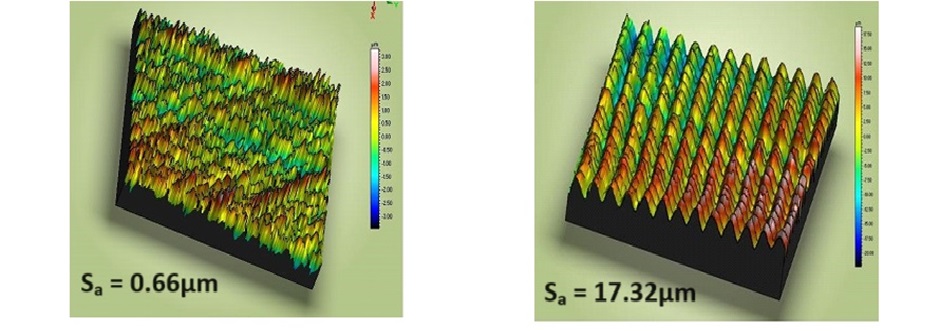

In order to obtain a superhydrophobic metal mold, studies were carried out on samples of aluminium-based alloy (Al) with lateral dimensions of 20 x 15 mm2 and 10 mm thickness. These aluminium surfaces were optically polished with a roughness Sa 0.66µm±10nm and also with water contact angle CA °=65.27±0.29. Before laser processing, the samples were cleaned by ultrasonic cleaning in acetone, ethanol solution and distilled water for 30 min in sequences.

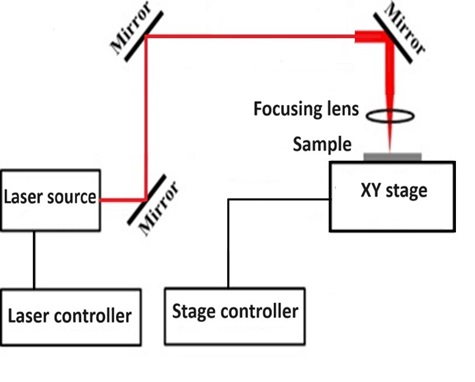

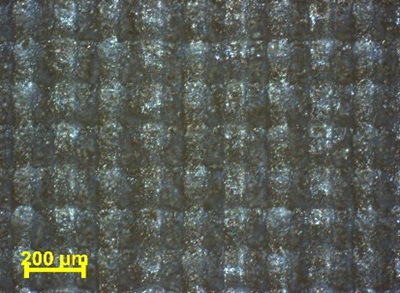

Schematic illustration of the set-up for laser irradiation experiment(left) and the surface of the ablated pattern(right)

The laser beam is directed towards the sample with the help of two mirrors covered with dielectric layers. The focusing lens is placed on a vertical displacement system (in the axis of the lens) to be able to correct the thickness variations of the samples. Optical lenses with different focal lengths (22, 50, 100 and 200 mm) were used to focus the beam on the target. The samples were irradiated in different environments (liquid and ambient environment). The distance between adjacent laser scanning lines, the so-called scan line separation or pitch size, was kept constant for both paths 150µm .

Surface characterization:

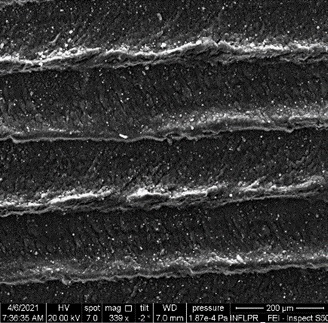

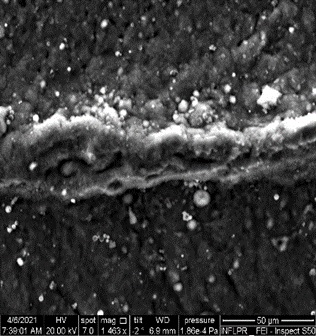

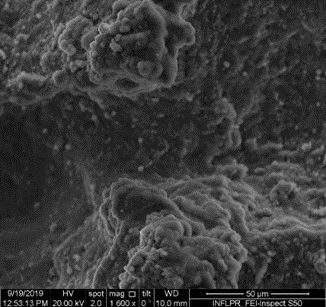

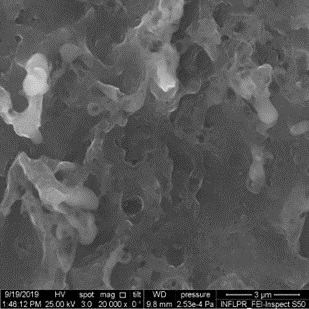

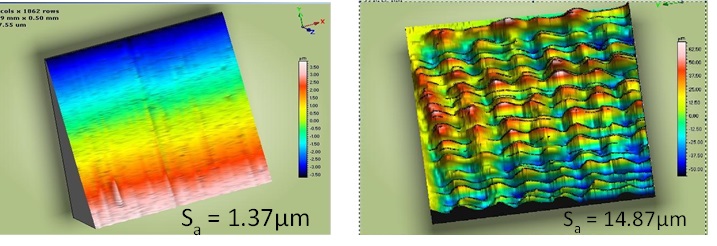

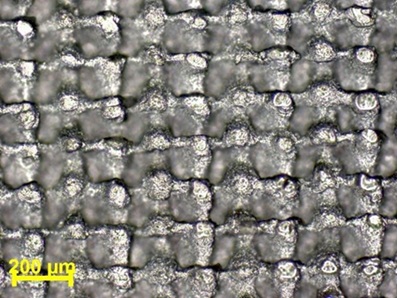

The Al surfaces was irradiated with different fluences at focal lengths between 100,50,22 mm in ambient and liquid environment. The morphology of these surfaces was characterized by optical microscope also, the topography surfaces -3D images of laser processed surfaces were obtained by profilometry. Using optical microscopy, we determined the optimal irradiation parameters for Al surfaces and using profilometry we established the optimal focal length in order to obtain superhydrophobic surfaces. With a nanosecond laser obtained the formation of burr on the surface. However, in performing this technique of obtaining superhydrophobic surfaces, precisely these burrs could act as microstructures capable of supporting water droplets and reducing the contact area between the metal surface and the water droplets, also to change the topography and surface composition.

The SEM images of the Al surface

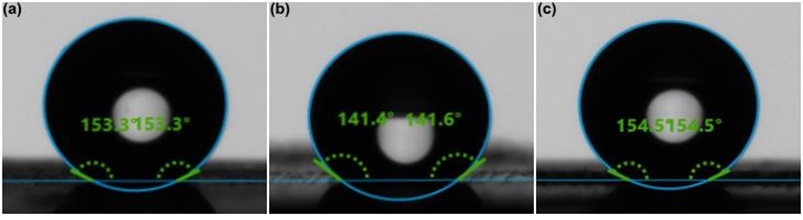

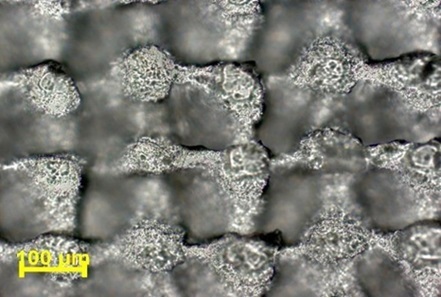

When the contact angle exceeds 150°, we are talking about the superhydrophobic surface (i.e. lotus effect, named after the superhydrophobic leaves of the lotus plant). The objective of this study was to obtain structured superhydrophobic metal surfaces by laser ablation and their replicas on polymer materials. The contact angles formed by the ultrapure water droplets on the laser ablated aluminium surfaces represented the main data of the study, together with the determination of the corresponding wetting diameters. The measurements were made using an optical drop profile analysis system (DSA25, KRÜSS). The generation of sessile droplets with a volume of 2 µl was achieved by means of the pressurized dosing subsystem (DS3252, KRÜSS), which facilitates the application of droplets on superhydrophobic materials. Aluminium surfaces irradiated with a laser beam in nanoseconds show a hydrophobic character, in many cases even superhydrophobic.

Contact angle for three aluminum samples

The surface of non-irradiated aluminium (left) and irradiated aluminium (right) considered as a mold

Results and discussions

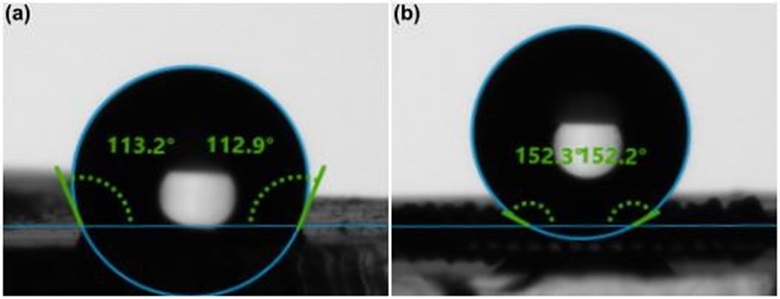

Replica of the aluminium surface on PDMS, the untreated area (left) and the irradiated area (right)

Optical images of the replica on PDMS

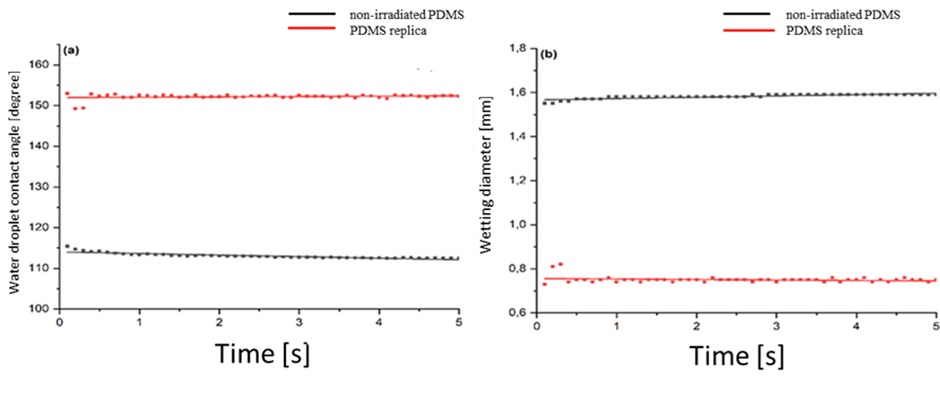

The contact angles obtained for: (a) non-irradiated PDMS and (b) PDMS replica

The evolution of the wettability of the non-irradiated PDMS and the PDMS replica.

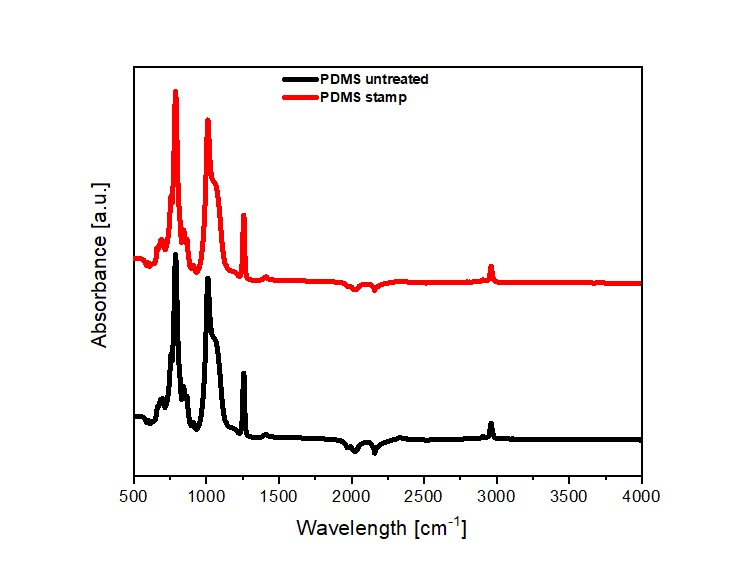

FTIR spectrum for untreated PDMS and PDMS replica

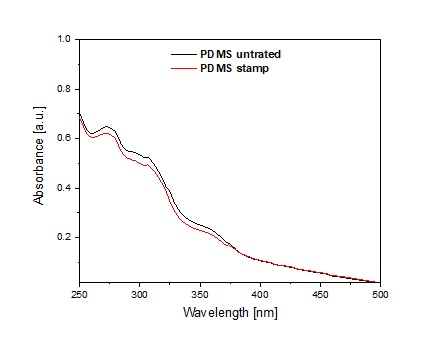

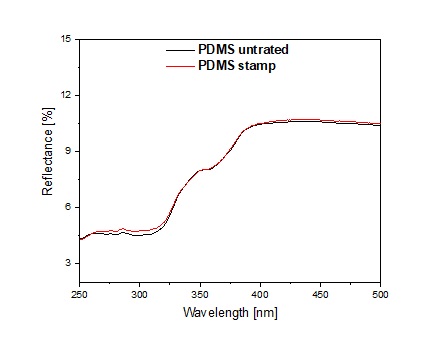

Absorbance and reflectance spectrum for untreated PDMS and PDMS replica

Conclusions:

In conclusion, by ablating a laser that emits in the nanosecond range on metallic aluminium surfaces, superhydrophobic surfaces are obtained, surfaces with contact angles greater than 150°. Due to the use of the laser in nanoseconds, burrs are formed on the ablated surface. Precisely these burrs act as microstructures capable of supporting the water drops and reducing the contact area between the metal surface and the water drops, which presents an advantage of using lasers in nanoseconds. Based on these molds replicas were obtained on PDMS, keeping the same characteristics with an aluminium surface, having a superhydrophobic character. The manufacturing method from this research is environmentally friendly, uses a flexible and low-cost system, which makes it promising for industrial production.